Efficiency that moves with you

Autonomous agents turning textile processes into seamless growth.

Textile Manufacturing Data at a Glance

Agentic AI takes care of your textile processes from yarn spinning to fabric inspection ensuring consistent quality, reducing waste.

10-25%

10-25%

10-30%

10-30%

10-20%

10-20%

10-20%

10-20%

Making Every Step in Textiles Effortless

Quality Control

AI-driven vision systems detect fabric defects in real-time, ensuring high-quality standards and reducing rework.

Production Efficiency

Automated scheduling and predictive maintenance minimize downtime and maximize throughput.

Sustainable Practices

AI algorithms analyze production data to identify areas for energy savings and waste reduction, supporting eco-friendly initiatives.

Data Insights

Real-time analytics provide actionable insights, enabling proactive adjustments and continuous improvement.

Effortless quality control with AI that thinks ahead

A leading textile manufacturer implemented Amantra’s AI solutions to automate fabric inspection processes. The result was a 30% reduction in defect rates and a 20% increase in production efficiency within the first quarter.

Case study

Solution Approach

Featured AI Use Cases for Textile

Fabric Inspection

Scan every inch of your fabric in real-time, detecting defects and inconsistencies before they reach production, ensuring flawless quality effortlessly.

Predictive Maintenance

Predict equipment issues before they happen, autonomously scheduling maintenance to keep your operations running.

Supply Optimization

AI monitors inventory, forecasts demand, and autonomously adjusts logistics to keep your supply chain lean, efficient, and responsive.

Energy Management

AI continuously analyzes energy usage, making real-time adjustments to minimize waste and drive sustainable operations.

Design Intelligence

AI studies market trends, customer behavior, and historical data to autonomously suggest innovative designs that hit the mark.

Quality Control

AI constantly monitors production quality, flags anomalies instantly, and takes corrective action where needed, reducing human error.

Why Choose Amantra for Textile?

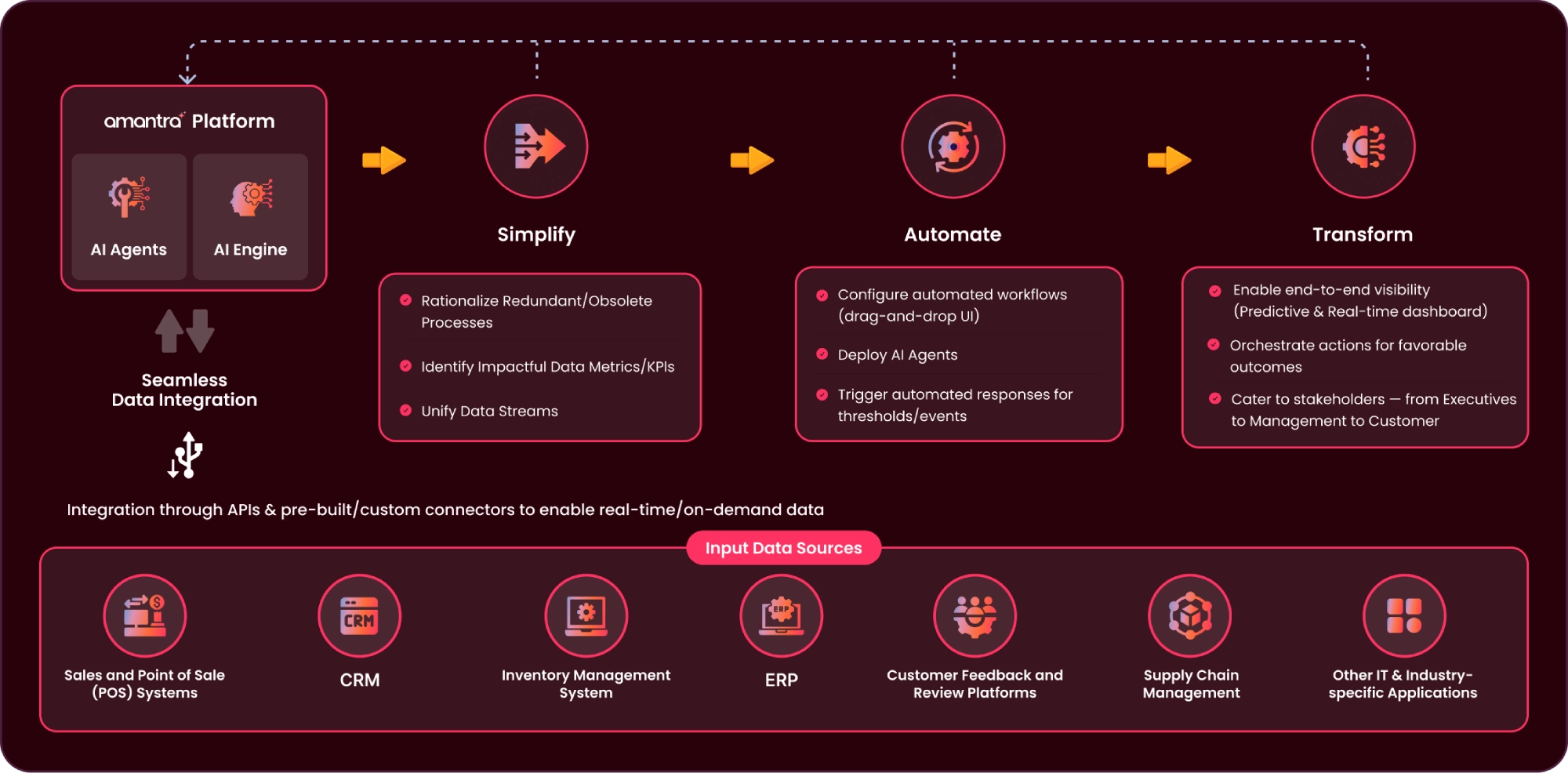

From seamless integration to real-time analytics, Amantra’s AI-driven automation solutions are designed to address the unique challenges of the textile industry. Optimize your operations, scale effortlessly to meet growing production needs, and enhance product quality and consistency.

Contact Us today to learn how we can help transform your operations.

Request a Demo